To explore the future of food facilities, every 3 years Wiley attends IFFA, the world’s largest meat industry trade show in Germany.

At this year’s IFFA, we saw:

✓ spiral freezers – common on our projects

✓ high-speed forming machines that stack, and

✓ pack, and precision dosing tech

One of the standout innovations was washdown robotics. These are hygienic, high-speed systems that pick and pack unpackaged food into trays and containers. Think of it as the future of meal assembly. No manual handling – just consistent, food-safe precision.

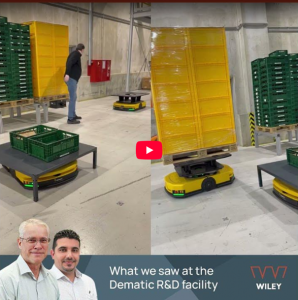

Pick-and-pack innovation was front and centre. A standout innovation making its debut was the magnetic rail transfer system. Unlike traditional conveyors, this system uses magnetic shuttles that glide independently along a track. Smooth, flexible, high-speed movement without belts or chains.

That means:

✓ faster changeovers

✓ cleaner lines, and

✓ more precise control

…which is perfect for food industry hygiene, custom routing and gentle handling. It’s smart, scalable tech that’s changing the way we think about food handling.

Wiley stays informed on the latest in food industry automation so we can bring the best solutions home to you.

Let’s talk next-gen food processing.

👉 connect@wiley.com.au